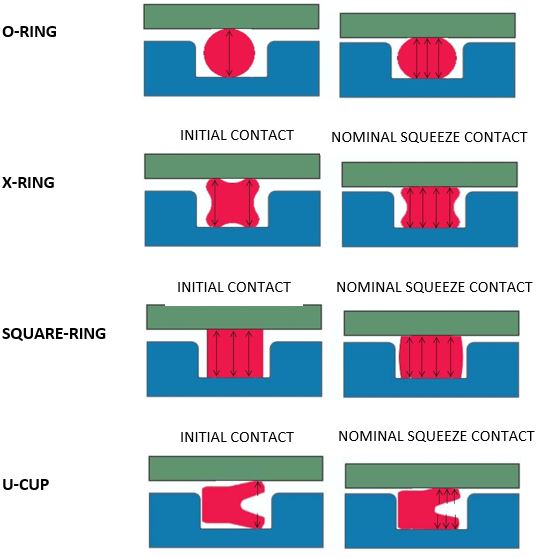

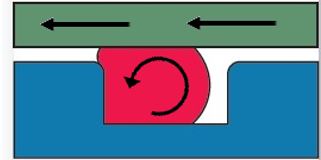

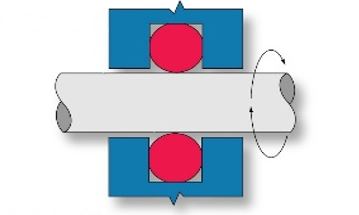

OSCILLATING SEALS In an oscillating Oring application, the shaft moves in an arc within the gland, and in contact with the ID of the seal Because there is a tendency for the shaft to twist, selflubricated Orings with a hardness of 80 to 90 durometer are most often employed Caution should be used, however, with graphitecontainingGeneral Engineering Menu ORings Suppliers Molded ORings Services ORings Design Guidelines, Specifications, Materials An Oring , also known as a packing , is a flexible gasket in the shape of a loop;Bearing rings for pistons;

Metric O Ring Groove Design Reference Guide

O-ring shaft seal design

O-ring shaft seal design-OIL SEALS & ORINGS CAT NO R01E4 Printed in Japan 'CDS (0701) OIL SEALS & ORINGS OIL SEALS & ORINGS CAT NOR01E4 Koyo Oil Seals Features Koyo ORings Features Koyo Functional Products Features FEM (Finite Element Method) Analysis 1 Oil Seals Engineering Section Dimensional Tables 2 ORings Engineering Section Dimensional Tables 3This Oring seal design section will give you step by step instructions on how to design a seal or rubber part for your application Consider this a rubber guide or Oring guide in helping you find the exact rubber material and size you need Some parts of this online rubber or Oring design guide can be downloaded in PDF but everything can just be printed directly from our website for your

Sealing High Speed Shafts In Turbomachinery Pumps Systems

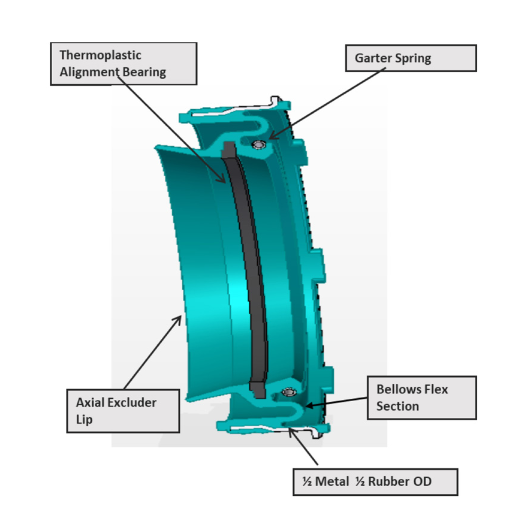

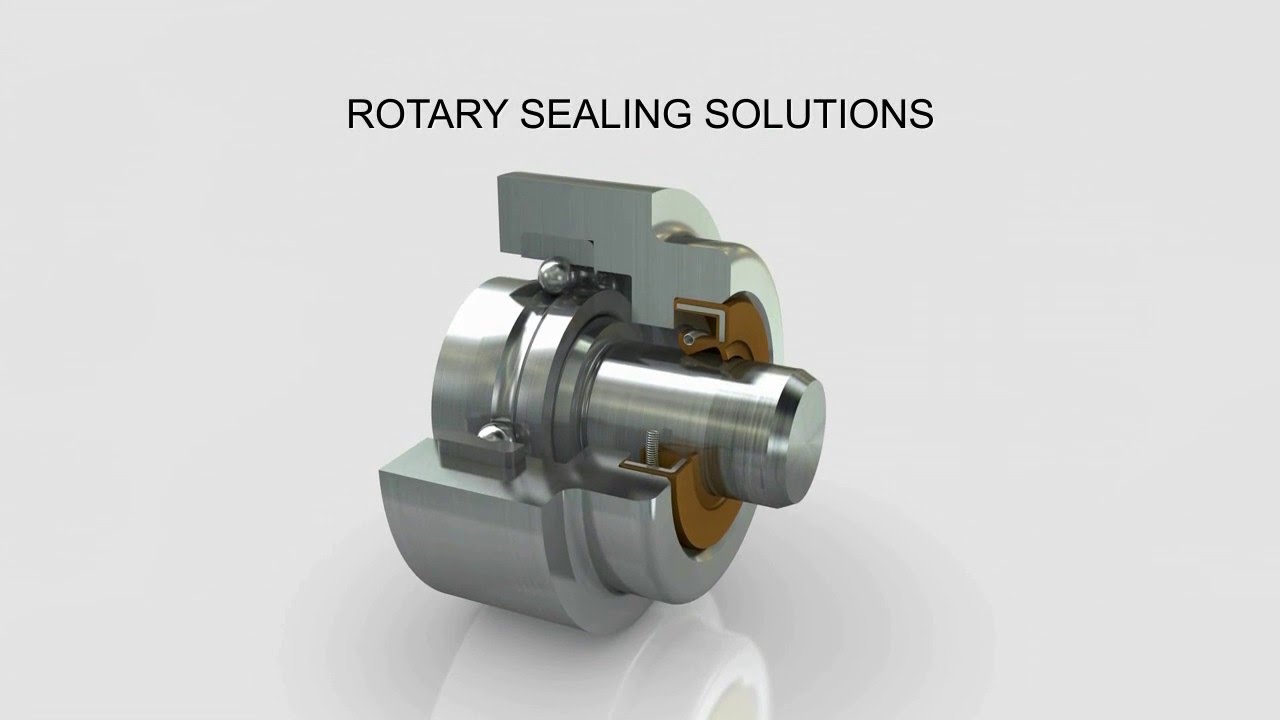

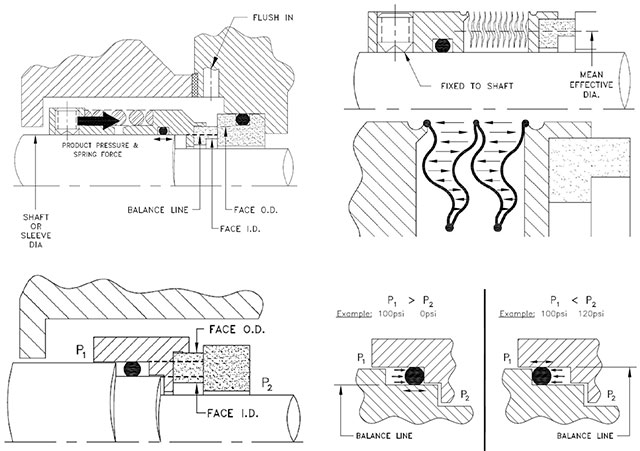

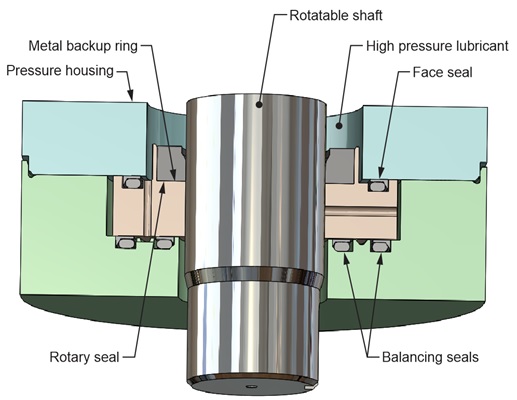

No dynamic oring eliminating the possiblity of hangups or shaft wear Hydraulically balanced metal bellows allow the seal to handle more pressure without heat build up Self Cleaning Centrifugal force throws solids away from the seal face – Trim design allow fit into tight seal boxes Even face loading No Springs to clog Most often metal bellows seals are thought of as HighThe oring seal design process begins with understanding the gland type in which the seal will be seated To ensure the oring fits properly it is recommended that the oring is stretched 1 to 5% circumferential, with ideal stretch at 2% Further considerations listed below include;Body design — Most Kalsi Seals are direct compression elements that are installed with radial squeeze, and seal statically in the same manner as Orings One type of Kalsi Seal is a springloaded lip seal design that withstands much higher pressures than conventional radial shaft seals They were developed for use in severe duty applications such as oilfield rotary control devices

M Seals specialises in seals for industrial use;This ensures a good contact to the ORing and prevents the seal from turning with the shaft The seal design ensures an efficient leakage control over the entire pressure range from 0 to 30 MPa The non stickslip properties of the Kefloy® compounds ensure a smooth operation The small installation dimensions allow a compact design of the hardware This is a major advantage in egFlange seal (figure 37) the ORing is compressed between two flat parallel surfaces and subjected to preloading deformation of an axial type Figure 35 Cylinder seal Figure 36 Piston seal Figure

Seal gland type, sealing application (fluid, solid gas), pressures, operating temperatures, and chemicalFor medium pressure and slow motion;SHAFT SEALS for easy cleaning;

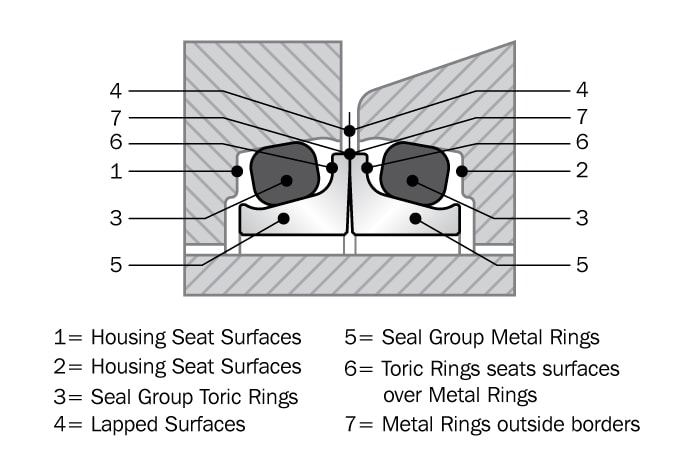

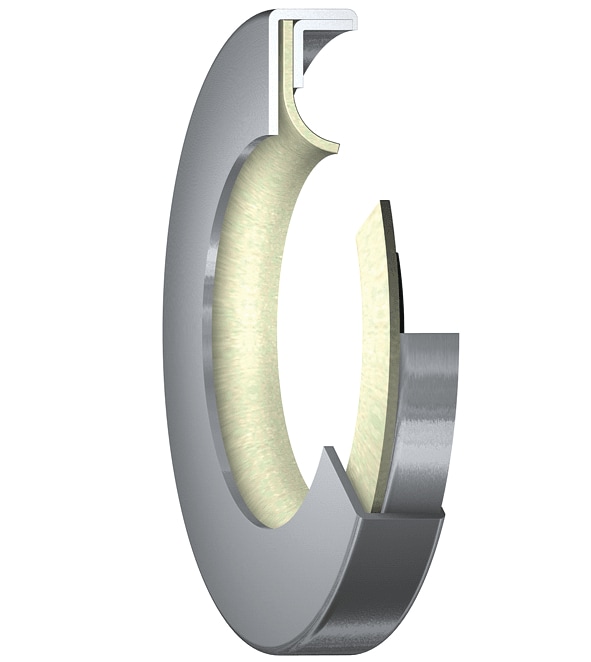

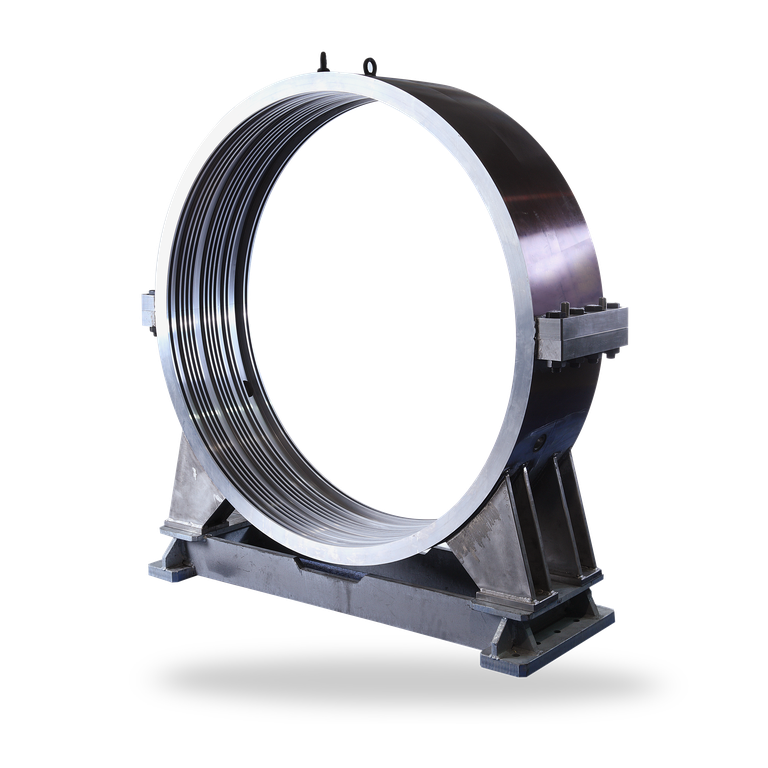

Mechanical Face Seals Heavy Duty Seals Trelleborg

Shaft Seal Ksb

It is a elastomer with a round crosssection designed to be seated in a groove and compressed during assembly between two or more parts, creating a seal at the interface• Housing design & tolerances • Cords, kits & lubricants Issue 7 2 To order or get further details, call your local contact shown on rear cover or listed at wwwjameswalkerbiz 'O' Ring Guide Introduction The 'O' ring, or toroidal seal, is an exceptionally versatile sealing device Applications, ranging from garden hose couplings to aerospace or oil and gas duties, make it theAn elastomer Oring is fitted to the outer diameter of the sealing ring, which provides the static seal between the sealing element and the bore We recommend clamping the shaft seals axially to prevent them from rotating The areas of application conform to the shaft sealing rings with stainless steel housing

O Ring Groove Design Global O Ring And Seal

Oring Ehandbook

Radial shaft seals with a low cross sectional height Cassette seals Wear sleeves Track pin seals Metal face seals Vring seals Axial clamp seals Sealing and spacing washers Hydraulic seals General technical information Piston Seals Rod and buffer seals Wiper seals Guide rings and guide strips Orings and backup rings Fluid The biggest weakness of radial Oring seals is that the clearance between components creates a path for the Oring to extrude due to the pressure acting on it Components called backup rings can help alleviate this Backup rings are designed to spring out of the gland and block the extrusion gap Where an Oring alone could withstand perhaps only 00 psi, aFrom the finest precision seals to the largest heavy duty shaft seals and packings Our products address the needs of customers that wish to have a broad range of products and solutions at hand The company was founded in 1963 and now has offices in 6 countries M Seals entered the UK market in 14 and through its 3 distribution

Type 48lp O Ring Pusher Seals John Crane Mechanical Seals

Untitled Document

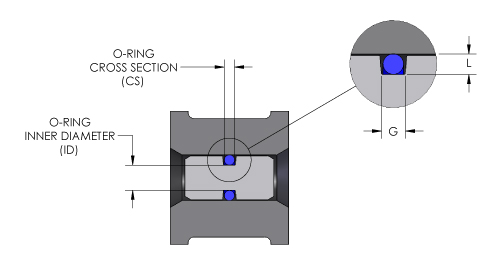

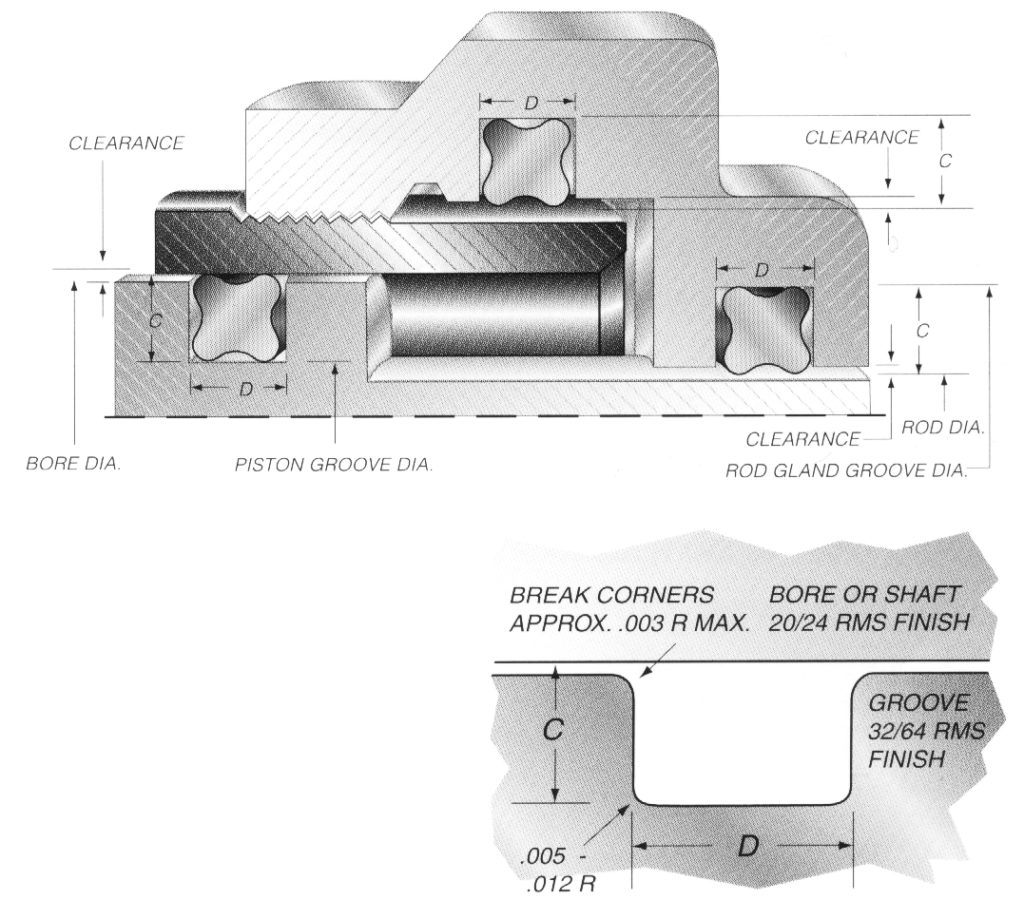

Oring gland design information Please contact the local ERIKS representative if an application does not clearly fall into these design parameters Static Applications There are five types of static Oring applications • Flange seal • Radial seal • Dovetail seal • Boss seal • Crush seal Flange Seal (Axial Seal) In flange seal glands, the two flanges are assembled with metal toFor a highpressure seal to work to optimal levels, oring design and manufacture again depends on choosing specific materials for better performance under specific conditions Orings function on the principle that even pressure placed on the (more or less incompressible) oring material creates predictable deformation patterns around the perimeter of the gasket in its groove ThisGroove Design ORing Seals for Static and NonRotary Dynamic Applications Speak to an Engineer About Your Project Crosssection Select an ORing crosssection size from the available standard sizes If you are unsure what crosssection size to use, see here Clearance Determine the maximum clearance present in your application For a radial seal, subtract the minimum rod

O Ring Groove Design Seal Design Inc

Johncrane Mechanical Seals Type 8 1t With O Ring Seat Rotary Shaft Seal To Replace Johncrane Seals 8 1t Good Quality From China Supplier Manufacturers Made In China Asino Sealing

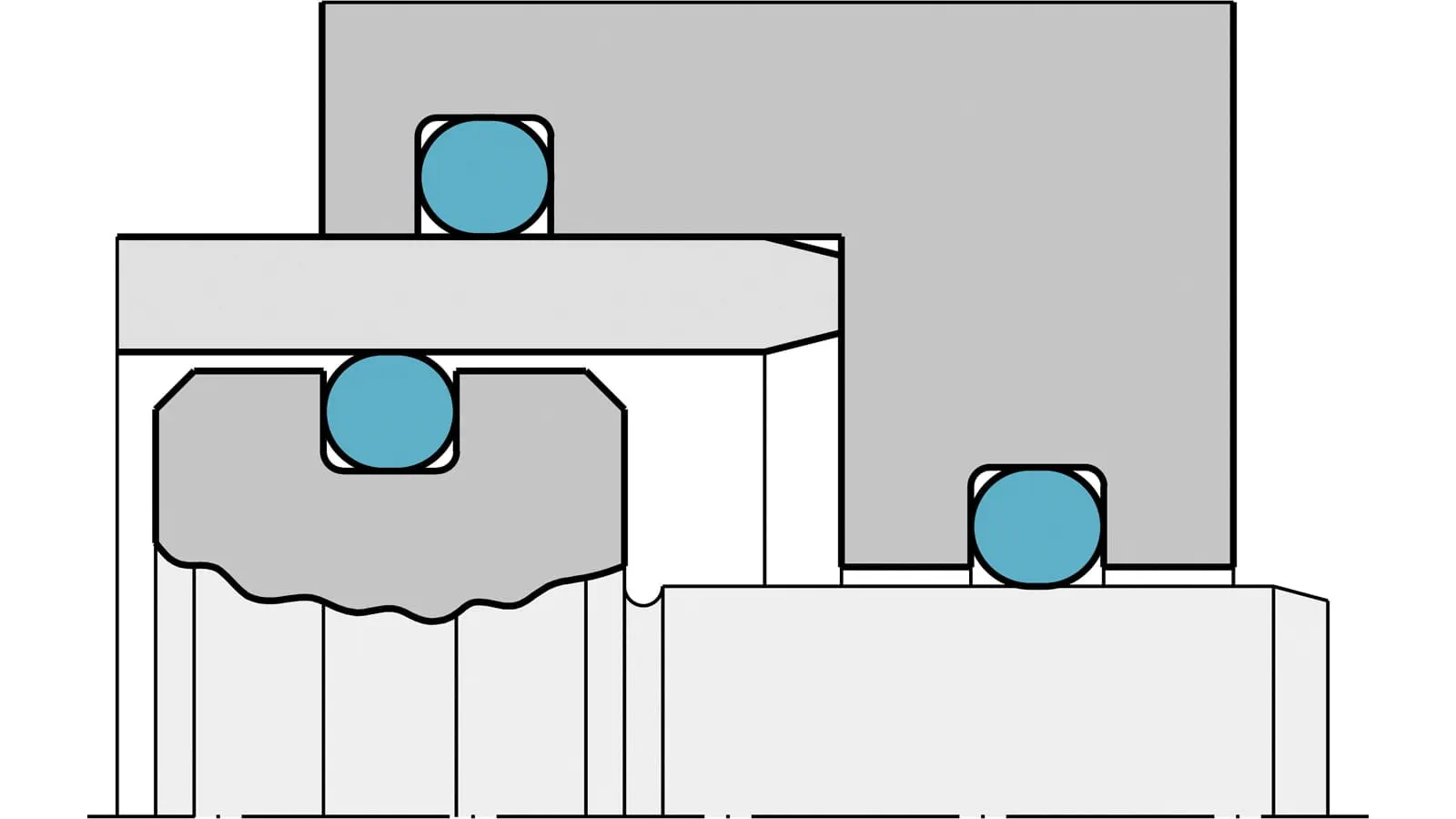

This innovative design combines a bracket bushing and seal gland made of hardened cast iron with two sets of double O ring seals giving reliable sealing with easy maintenance The pair of static Orings seal externally on the bracket and the pair of dynamic Orings seal internally on the shaft, preventing process fluid from leaking out of the pump and reducing wear between the shaft andAXIAL SEALS Axial sliding ring;The elastomer oring concept has been explored in two addi¬ tional ways These are the use of orings of small cross section in the tongue and groove flange design and the use of orings between flat plates Viton A^ ^ orings of 1/16 inch cross section diameter have made satisfactory seals in a tongue and groove flange design and

Radial Shaft Seals Freudenberg Fst

Practicalmaintenance Net

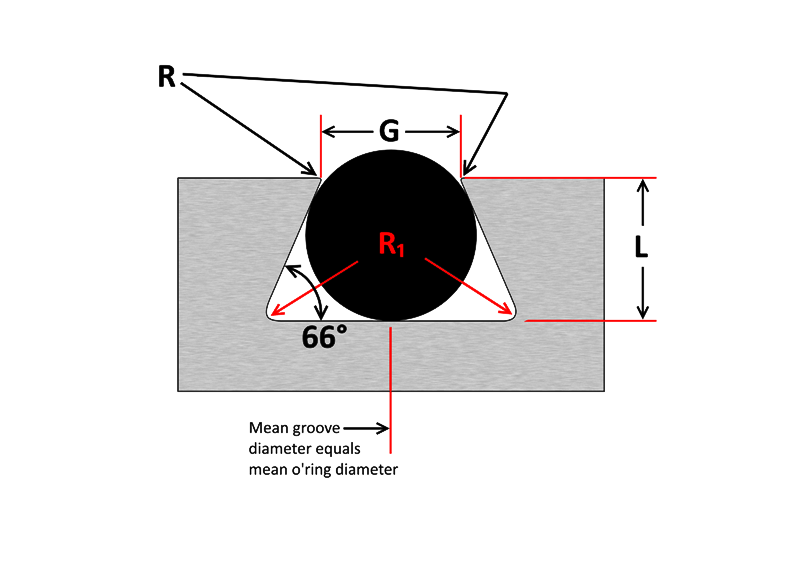

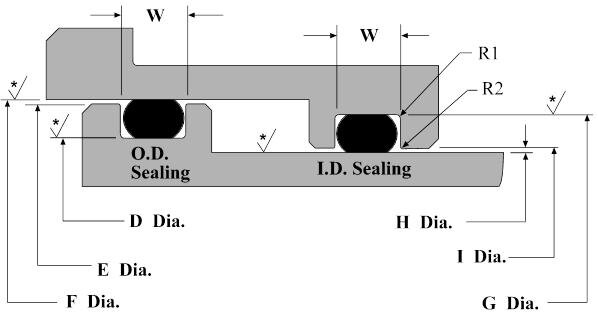

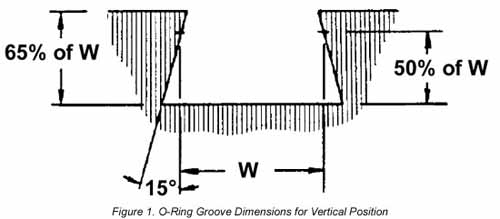

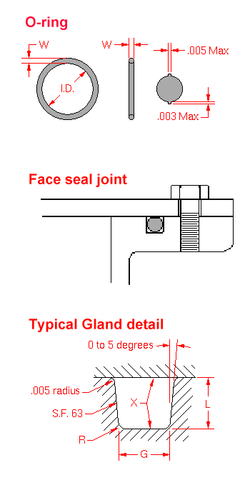

O'ring Groove Design As important as the o'ring seal itself is the groove that the o'ring seats into The groove must be designed to accommodate not just the o'ring size, but also its intended usage;Orings and backup rings maintain sealing contact force by radial or axial deformation in the seal housing between two machine components The most important criteria that influence the maximum operating pressure at which Orings in static radial sealing can be usedSeal & Design is a worldclass seal & gasket manufacturer and a name you can trust for gasket, seal and oring solutions Technical sealing has been defined by DIN Standards as follows • Static Seal – The sealing action created between two mating surfaces with no leakage of liquid or minimal diffusion of gas • Dynamic Seal – The mating surfaces have relative movement with minimal

Duramax Marine Shaft Sealing Systems Drymax Stern Tube Seals

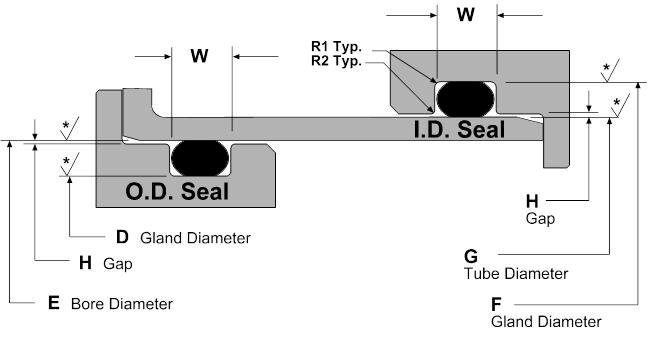

Dynamic Rotary Gland Design Dynamic O Ring Gland

BEARINGS Bearing rings for rods;Rubber Seals, Sealing Devices & ORing Seal Design AppleAdditional HDS design options ;

Dynamic Reciprocating Gland Design Dynamic O Ring Gland

Sealing High Speed Shafts In Turbomachinery Pumps Systems

A cutaway view of a fuel injector with Oring seals is shown in Fig 136 2 In common with other fuel system seals, fuel injector Orings must be resistant to compression set for very long periods In addition, fuel injector Orings are subject to excursions to very high temperatures such as 125–150°C (257–302°F) that occur in the engine compartment Many seal specifications includeBe it dynamic or static operation, radial or axial loading, vacuum or high pressure The following information is a guide for o'ringWIPERS/SCRAPERS for rods ;

What You Need To Know About Dynamic Seal Applications Hot Topics

Oring Ehandbook

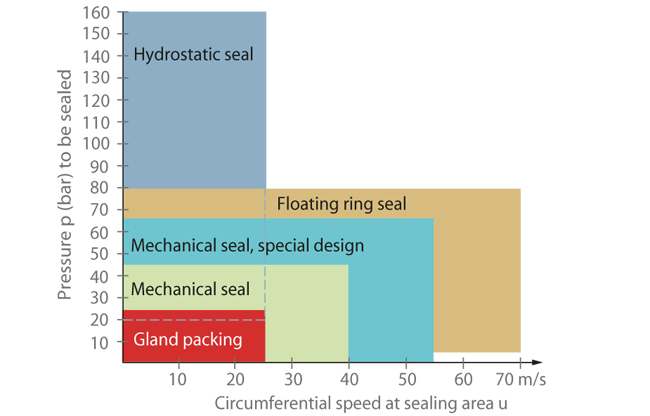

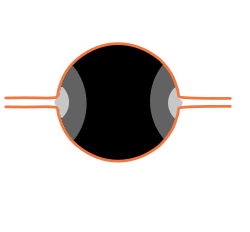

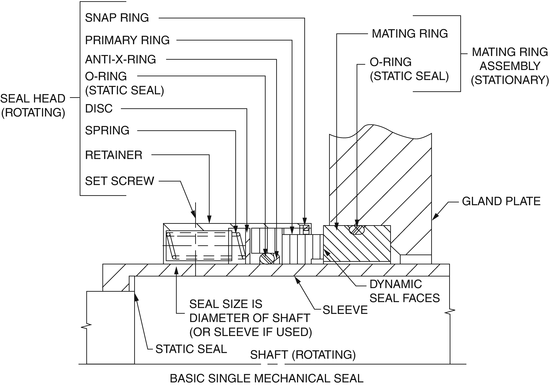

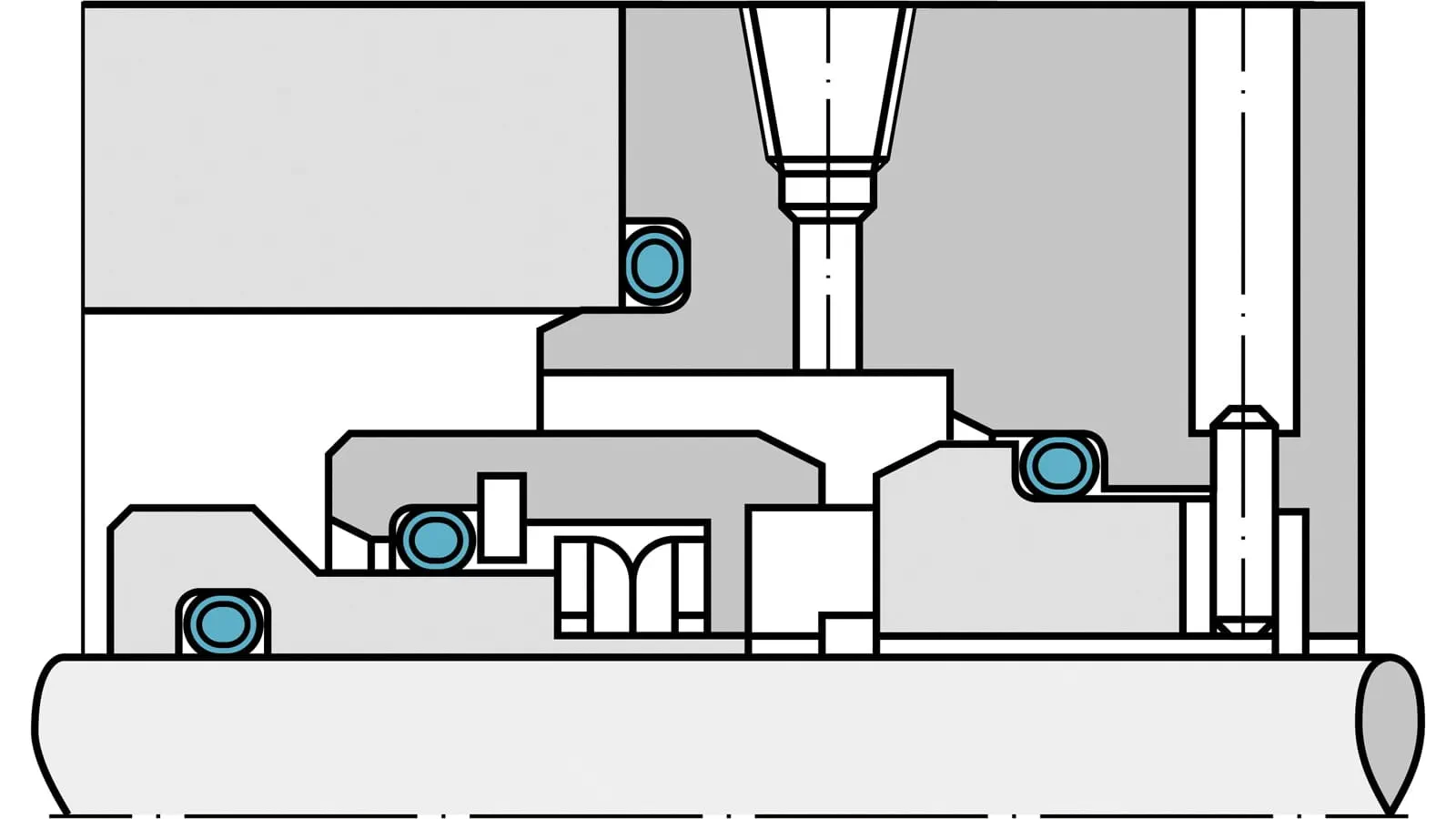

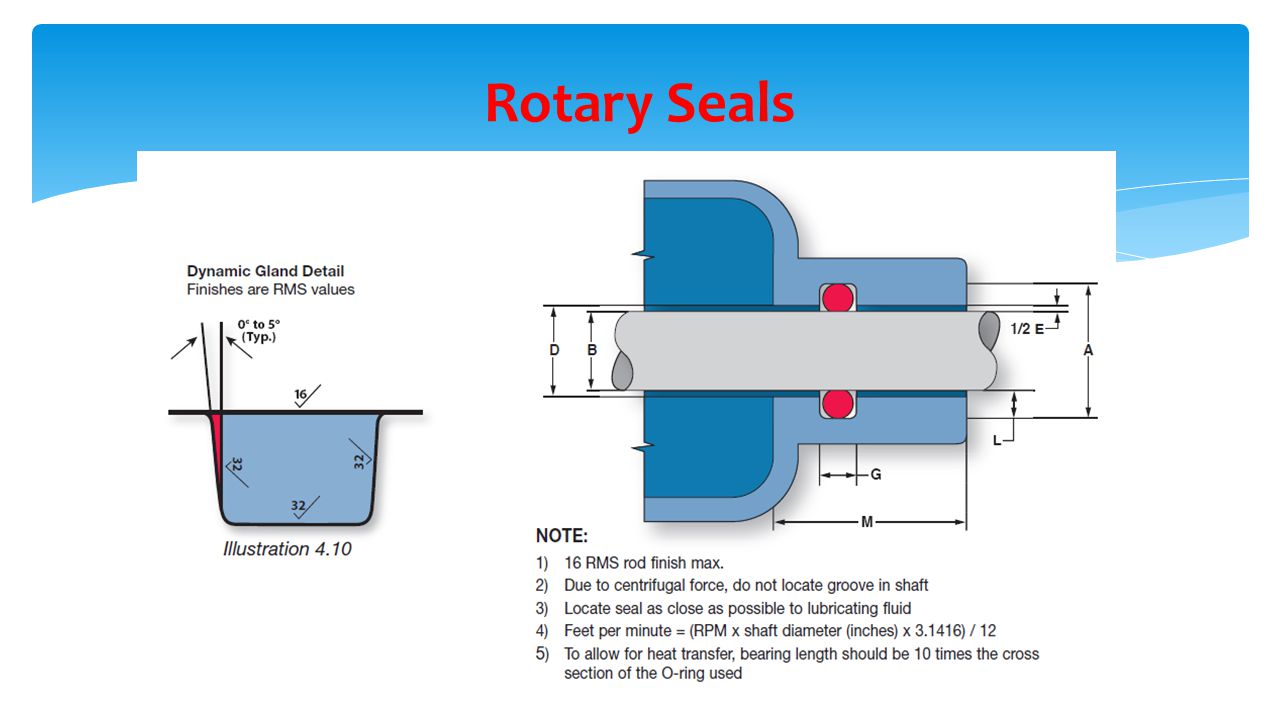

Dynamic Rotary ORing Gland Design In a dynamic rotary seal applications a turning shaft protrudes through the ID of an oring, the oring then becoming a seal The table below lists recommended dimensions for dynamic rotary seal glands by AS568A oring dash numbers Static Radial Glands Axial Internal PressureMechanical shaft seal Oring, stationary Oring, rotating Spring Torque transmission element Introduction 3 Operating principle This section describes how the lubricating film is generated in the sealing gap in a liquidlubricated mechanical bellows shaft seal The design differs slightly from the Oring seal shown in fig 19 In its simplest form, the mechanical shaft seal consists ofThe appropriate seal type for the individual pumping requirements is chosen from a wide variety of different shaft seals The design is based on one of the two following principles sealing by means of a narrow radial gap (parallel to the shaft axis) or a narrow axial gap (at a right angle to the shaft axis) For both sealing principles, the gaps may either employ a contact or noncontact

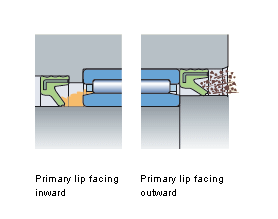

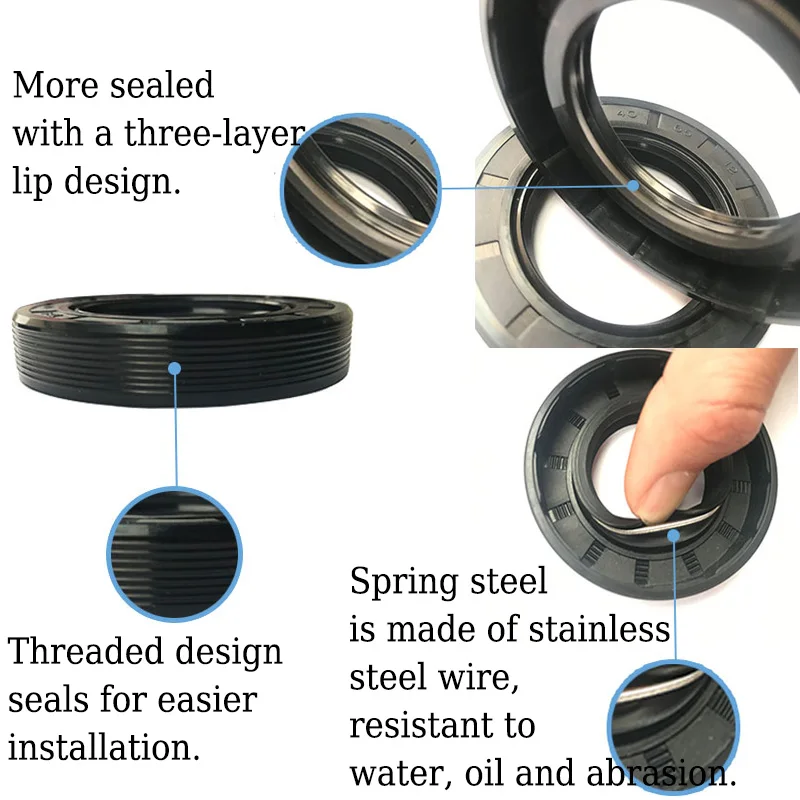

Oil Seals Lip Seals Rotary Shaft Seals Buy Online Polymax Uk

Panaceal Sdi

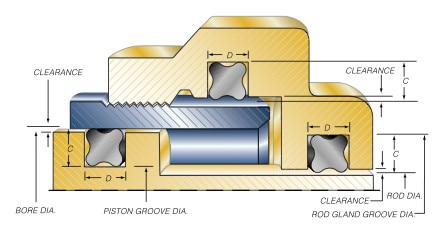

Our V ring seals are available in both Nitrile and Viton rubber V rings are located on the shaft and rotate with it, keeping lubricants in while ensuring grit, dirt and moisture are kept out The choice of rubber determines their resistance to temperature variations and chemicals, with Viton versions generally being the more durable choice Nitrile shaft seals are used as oil seals and areThose who are already familiar with Oring seal design may simply refer to the appropriate design tables for the information needed Even those who have designed many Oring seals may profi t by reviewing the basics from time to time 11 What is an ORing?5314 ORing Glands for Rotary Seals Design Chart 54 provides the basis for calculating gland dimensions For standard Oring sizes, these dimensions have been calculated and are listed in Design Table 54 The procedures for the use of Design Table 54 are outlined in Design Guide 54 below After selecting gland dimensions, read horizontally to determine proper Oring size

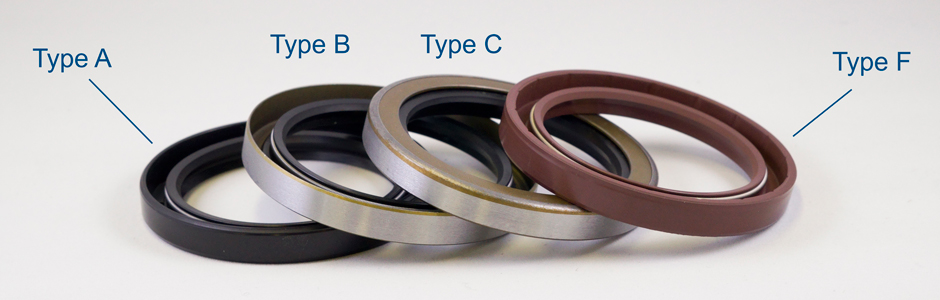

Inch And Metric Oil Seal Types Gbsa Oil Seal Manufacturers

Types Of O Ring Applications

SPLIT SEALS 3710 Split ORing Split Seal The Type 3710 Cartridge Split Seal is the latest innovation in the evolution of split seal designs It utilizes John Crane's advanced split seal technology to meet today's environmental guidelines and future regulations Its unique, easytoinstall design readily adapts to horizontal and vertical pumps, mixers, and agitators The TypeSeal ring design makes it very difficult to install or remove Embedded in the inside diameter of the seal ring are two Orings that keep water from leaking past the seal ring into the vessel The seal ring inside diameter is only slightly larger than the diameter of the propeller shaft This close tolerance between the shaftAn Oring is a torus, or doughnutshaped ring, generally molded from an elastomer, although Orings are also made from PTFE

Oil Seals Radial Oil Seals Trelleborg

O Rings O Yeah How To Select Design And Install O Ring Seals Tarkka

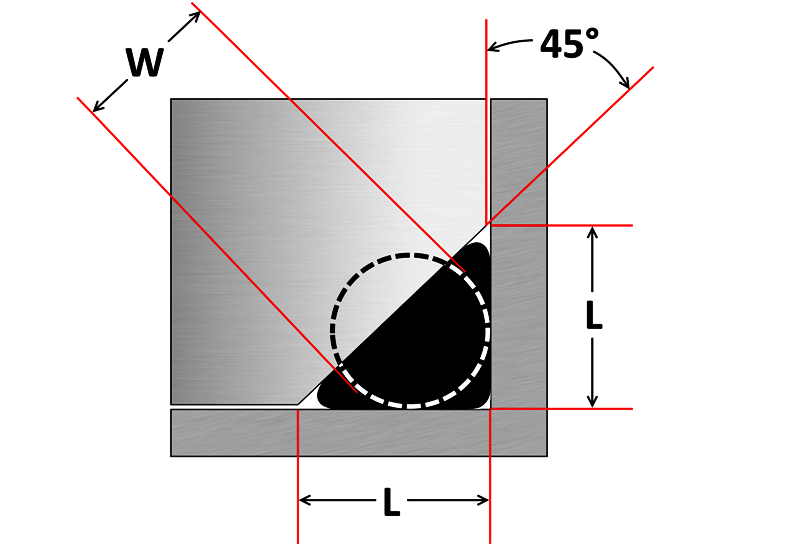

An Oring has proved to be a practical rotary shaft seal in many applications With the correct design, Parker ORing rotary seal compound N, will provide satisfactory service at surface speeds up to 1500 feet per minute The design conditions are most critical for rotary seals, as would be expected Relatively high durometer compounds, close control of tolerances, andORing Basics The Parker ORing eHandbook is a condensed online version of the printed Parker ORing Handbook ORD 5700 For those who are unfamiliar with Oring design, it is recommended to first study this introductory section, becoming familiar with the basic principles of Oring sealing, their common uses and general limitationsOring Gland Design Dovetail seal Also here there is a metal to metal contact as long as the construction will not deform under system pressure (fig 130) Boss seal The groove dimensions are incorporated in the standard dimensions Surface Finish Static Grooves Straightsided grooves are best to prevent extrusion or nibbling Five degree sloping sides are easier to machine and are

1

At Discount O Ring Seal Design Spring Customization For Oil Lepu

For high pressure and slow motion;More than just seals Welcome to the BSCL We are a specialist provider of Orings, hydraulic seals, gaskets, fasteners and turned parts with over six decades' combined experience responding to the needs of a broad range of industries How we can help your business At BSCL, quality and service is our way of life We aim to respond to theDesigning the parts of an application where orings will be applied is broadly termed "oring groove design" In order to seal properly, the oring has to deform in the application by being compressed and stretched in any number of ways The design of the groove where the oring sits plays a major role in how the oring performs its sealing role Extrusion Limits;

Static O Ring Design Chart Marco Rubber Plastics Custom O Rings Supplier

Groove Design Quad Ring Seals Minnesota Rubber Plastics

To find the groove dimensions on a rotating seal, use Design Chart 5 Find the shaft size in the second column The groove root diameter and width will be found under their respective columns The Pressure Seals Oring size will be found in the first column next to the shaft diameter BACKUP RINGS (Design Chart 7) When you have a tendency for Orings to extrude between theIf the bore or shaft size you are using is not listed, select the ORing with an inside diameter just smaller than the shaft you are using If you are designing a face seal, select the ORing with an inside diameter which will position the ORing on the side of the groove opposite the pressure Click here for more information on face seal groove design Note the ORing inside diameter forOur oring groove design guides list default oring groove dimensions for the most basic applications and are intended to be used with the following oring groove design considerations to engineer on oring gland to optimize specific application performance The wrong size groove makes even the best oring underperform Trust and Choose Marco Rubber & Plastics For more

Pool Pump Shaft Seal O Ring Seal Design Lepu

Seal Category Radial Shaft Seal Freudenberg Sealing Technologies

SEALING AND BEARING BUSHES;ERIKS standard ORings and load them also into your created design info chemical volume swell (%) cross section diameter (mm) ISO 3601 free Calculate Results Reset calculatorThe squeeze or rate of compression is a major consideration in Oring seal design Elastomers may take up the stackup of tolerances of the unit and its memory maintains a sealed condition Orings with smaller cross sections are squeezed by a higher percentage to overcome the relatively higher groove dimension tolerances 3 Application Design Orings can be successfully used in static

O Rings O Yeah How To Select Design And Install O Ring Seals Youtube

Your Guide To Choosing The Best Rotary Shaft Seal

Created Date AMAn Oring seal is one of the most widely used seal to block the clearance gap in the industry today It is also known as toroidal seal Oring seals are used in applications, ranging from garden hose couplings to aerospace or oil and gas duties due to the following advantages Wide application range (pressures, tolerances, temperatures, media) No retightening required No critical torqueThe Deep ORing Loaded UCup design is a modified version of the Standard's square shape This design has approximately 11/2 times the axial depth of the Standard seal which greatly adds to the stability of the design in higher applications Generally you would have to make gland modifications for this seal when replacing ORings but this design is ideal for replacing V or W packing or

High Deflection Seals Solving Seal Leakage From High Shaft Deflection And Alignment Problems

Practicalmaintenance Net

Piston seal (figure 36) the ORing is inserted in a seat machined on the component which constitu tes the shaft of the assembly, and the preloading deformation for the seal is of a radial type;10 ORING SEALS – THEORY AND DESIGN PRACTICES Theory An oring seal consists of an oring and a properly designed gland which applies a predictable deformation to the oring The gland is basically a groove dimensioned to a certain height "H" and width "W" (Figure 1) to allow a fixed compression of the oring when the gland flanges make metal to metal contact It is also

O Ring Groove Design Sealing Australia

Rotary Seals Design For Construction Machinery Dms Seal Manufacturer

Seal Design O Ring Design O Ring Design Guide

O Ring Groove Design Daemar Inc

O Ring Groove Design Sealing Australia

Seal Analysis Pays

Design Of Oring Seals Design Of Oring Seals

Rubber Rotary Shaft Seal Water Seal Shaft Use V Ring Types Fkm Vl Va Vs Ring Nbr Rubber Va Type Water Seal Buy Water Seal Va Type Water Seal Rubber Va Type Water

Self Centering Seals Design

Johncrane Mechanical Seals Type 8 1 With O Ring Seat Rotary Shaft Seal To Replace Johncrane Seals 8 1 Good Quality From China Supplier Manufacturers Made In China Asino Sealing

Oil Seal Design Selection Gbsa Inc

Rotary Sealing Solutions Radial Oil Seals And V Rings Youtube

O Ring Groove Design Global O Ring And Seal

Rotary Shaft Seals

Design Of Oring Seals Design Of Oring Seals

O Ring Groove Design Sealing Australia

Ptfe Seals Skf

Rotary Shaft Seals Seal Design Inc

O Ring Groove Design O Ring Groove Dimensions Mykin Inc

What You Need To Know About Dynamic Seal Applications Hot Topics

Untitled Document

Water Seal Rubber V Seal V Ring Va Vs Vl Rotary Shaft Seal Ring Buy Rubber V Seal Vs Ring V Seal Product On Alibaba Com

Quad Ring Groove Design Daemar Inc

Groove Design O Ring Seals Minnesota Rubber Plastics

How To Choose O Ring For Your Seal Sealwise Co Ltd

China Tg4 M16 Profile Ptfe High Pressure Radial Shaft Seal Ring China Shaft Seal Radial Seal

What Are Rotary Shaft Seals Cinchseal

O Ring Groove Design Standard As568b Seal Design Inc

1

Shaft Seals En

Design Of Oring Seals Design Of Oring Seals

O Ring Wikipedia

Shaft Seals For Rotating Shafts

O Rings Archives Polymax Blog

O Rings O Yeah How To Select Design And Install O Ring Seals Tarkka

Self Centering Seals Design

Sealink Sealing Mechanism Lubricant Free Mechanical Seal Design Sealink

What You Need To Know About Dynamic Seal Applications Hot Topics

O Ring Groove Design Global O Ring And Seal

Single Seals For Caustic Environment In Pumps

Protech Bearing Isolator Made By Parker The Hope Group Largest Parker Distributor In New England

Mechanical Seals Springerlink

Specification For Low Cross Section Seals Skf

What You Need To Know About Dynamic Seal Applications Hot Topics

Fep O Rings Trelleborg Sealing Solutions

Elastomeric O Rings Trelleborg Sealing Solutions

Customized Viton Quad Ring For Dynamic Seal Manufacturers Suppliers Factory Direct Wholesale Xlong

Dynamic O Ring Design Chart Marco Rubber Plastics Custom O Rings Supplier

1

Shaft Seal For Linear Motion Reciprocating Shaft Seal France Joint

China Accept Custom Design Stellite O Ring Mechanical Shaft Seal Ring On Global Sources Carbide Oem Ring With Holes Finish Machining Mechanical Seal Ring Hard Metal Torus With Holes

Fundamental Of O Ring

Top 3 Mechanical Seal Ring Design Considerations Flexaseal Engineered Seals And Systems

Seal Solutions Guide

Customized Black O Ring Cord For Sealing Manufacturers Suppliers Factory Direct Wholesale Xlong

Types Of Seals A Thomas Buying Guide

Mating Ring An Overview Sciencedirect Topics

Llis

All Seals Inc The Sealing Specialists

Rotary Sealing With High Pressure Seals Kalsi Engineering

2 Pcs Tg4 Skeleton Oil Seal Radial Shaft Seal Nitrile Rubber Sealing Gasket Id 45 Mm Sealing Ring Gaskets Aliexpress

O Ring Info

Metric O Ring Groove Design Reference Guide

Fundamentals Of Mechanical Seals Seal Faqs

Design Of O Ring Seals Ppt Video Online Download

1

Kurt J Lesker Company Dynamic O Ring Shaft Seal Vacuum Science Is Our Business

Hitechseals Com

Rotary Shaft Seals

O Ring Wikipedia

Diagram Of The Face Seal Design 1 Seal Ring Flexibly Attached 2 Seal Download Scientific Diagram

Pressureseal Com

0 件のコメント:

コメントを投稿